Posted on August 10, 2022

Prime Filter Press Manufacturer With Rich Experience

At M.W. Watermark, we are focused on our clients and our planet.

M.W. Watermark is focused on giving industry driving gear, administration, and bearing. We work in a family-situated climate with faithful representatives who have been with us for a very long time. The Micronics Engineered Filtration Group will assist you with accomplishing your creation objectives, with Engineered Filtration Solutions suitable for your industry application, and set of working circumstances. Shriver® Filter PressThe Shriver® Filter Press is a basic player in upgrading your dewatering cycle no matter what your industry.

Numerous regions and driving businesses are currently changing concentration and dealing with their Biosolids by dewatering. The rental and renting of Dewatering Equipment has turned into filter press manufacturer a more normal answer for districts and enterprises. We have made the offered items accessible in various details to satisfy unique needs of the clients. Adjusting to the characterized boundaries of the business, these offered items are flawlessly eliminate slime from mineral slurry from 6-25% solids and muck from 1-6% solids.

We stock bearing gatherings, seals, gaskets, rollers, specialist sharp edges, guiding valves, furrows and numerous other extra parts. Jingjin is the constitutor of standard of China channel press industry. Jingjin has close specialized trades and collaboration with world top channel press providers, and we give channel plate and fabric and different embellishments for them. Jingjin partake in the worldwide business notable innovation trade meeting consistently. Client’s input and trust give us limitless advancement and improvement.

The filtration plates are suspended on it making the channel press inflexible to endure solid power stacking during the functioning cycle.

The filtration plates structure the functioning room of the channel press – an arrangement of shut filtration chambers. The side of the plate is thicker than the inner recessed part and subsequently it makes contact surfaces with the nearby plate. The filtration chamber is constantly comprised of two contiguous plates, the thickness of the not entirely set in stone by an amount of their downturns. The dewatered suspension is passed on through the channel opening going through the entire arrangement of plates and garments. The fluid is disseminated equally by strain to all chambers, the filtrate goes through the garments and is depleted by means of directs penetrated in the plates.

Southern Filtration Products of Porter, TX highlights 30 years of involvement offering quality assistance and reseller’s exchange parts support for screening, dewatering and drying gear. Channel cake pipes are introduced between the channel press, the stage, and the ideal exchange point. This serves, for instance, in blend with a transport for the designated release of the channel cake for gravimetric filling in supposed Big Bag Filling Stations. Whenever wanted, channel cake containers can be given an upkeep opening on the front side.

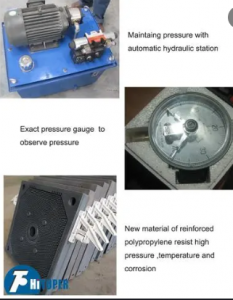

A base channel gives strain because of which all of the fluid that is unfiltered is midway taken care of. 3.Plate is made of unadulterated pp material so that guarantee really high separating strain to 1.5 MPa or higher. 1.Fully programmed control.From taking care of to releasing, it embraces unattended activity. The table beneath shows just characteristic data for the filtration chamber thickness of 25 mm. As respects the layer plan, the volume expressed is the volume prior to pressing the films. Alongside the conveyance of our gear we ensure conveyance of working documentation, preparing of faculty and administration staff , assurance and post-ensure administrations , and specialized help.