Updated on March 14, 2024

Boost Efficiency with Filter Press Membrane: A Game-Changer in Solid-Liquid Separation

This article explores the applications and benefits of filter press membranes in various industries. The quick opening and high-pressure capabilities of these membranes make them a popular choice for efficient solid-liquid separation processes. The article highlights the key features, working principle, and advantages of using filter press membranes. It also provides examples of industries where these membranes are widely used.

Introduction:

Filter press membranes have revolutionized the solid-liquid separation process in mining, chemical, and wastewater treatment industries. These membranes’ quick opening and high-pressure capabilities make them an ideal choice for improving efficiency and reducing operating costs. This article delves into the applications and advantages of using filter press membranes, shedding light on their importance in various sectors.

Applications of Filter Press Membrane:

1. Mining Industry: In the mining industry, filter press membranes are used to separate solids from liquids in mineral processing. They aid in the dewatering of mining slurries, allowing for the recovery of valuable minerals and reducing the volume of waste materials. The high-pressure capability of these membranes ensures efficient separation and faster cycle times.

2. Chemical Industry: Chemical manufacturing processes often involve the separation of solids from liquids. Filter press membranes play a crucial role in achieving this separation, ensuring the purity of the final product. They are popular in processes such as catalyst recovery, pigment filtration, and wastewater treatment.

3. Wastewater Treatment: Filter press membranes are extensively used in wastewater treatment plants to remove solids from the wastewater stream. These membranes effectively separate the sludge from the liquid, allowing for the proper disposal or further treatment of the sludge. The quick opening feature of these membranes enables faster and more efficient filtration, reducing the overall treatment time.

Working Principle of Filter Press Membrane:

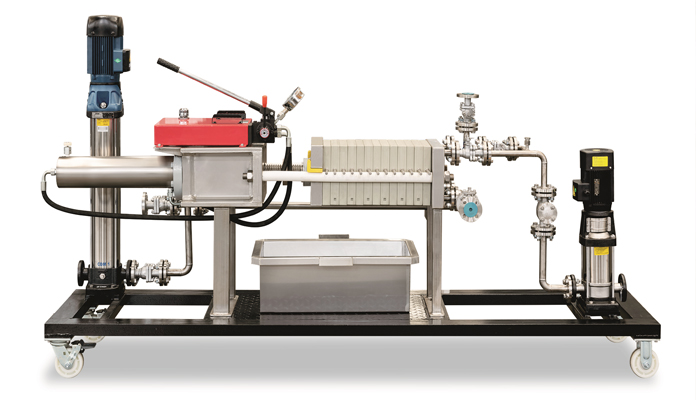

Filter press membranes operate on the principle of pressure-driven filtration. The filter press consists of a series of chambers with filter plates and filter cloths. When the slurry is pumped into the chambers, the solids are retained on the filter cloth, while the liquid passes through. The filter press membrane on one side of the chamber applies additional pressure to squeeze out more liquid, resulting in a drier cake.

Advantages of Using Filter Press Membrane:

1. Improved Efficiency: The quick opening feature of filter press membranes allows for faster cycle times, increasing the overall filtration efficiency. This results in reduced operating costs and improved productivity.

2. Higher Solids Recovery: Filter press membranes ensure maximum solids recovery, minimizing product loss and reducing waste generation. The high-pressure capability of these membranes aids in achieving a drier and more concentrated cake.

3. Cost Savings: By optimizing the solid-liquid separation process, filter press membranes help reduce energy consumption, chemical usage, and disposal costs. The efficient filtration process also leads to extended equipment lifespan and reduced maintenance requirements.

Conclusion:

Filter press membranes have become an indispensable tool for efficient solid-liquid separation in various industries. Their quick opening and high-pressure capabilities offer numerous benefits, including improved efficiency, higher solids recovery, and cost savings.

By utilizing filter press membranes, industries can enhance their productivity, reduce operating costs, and contribute to sustainable practices. Embracing this technology is a game-changer in achieving efficient solid-liquid separation processes.