Updated on October 16, 2023

Efficient Filtration: The Power of Filter Press Cloth

Filter press cloth plays a crucial role in separating solids from liquids efficiently and effectively. Learn about the function, materials, and applications of filter press cloth. Explore how this essential component optimizes filtration, enhances productivity, and ensures the quality of filtered liquids.

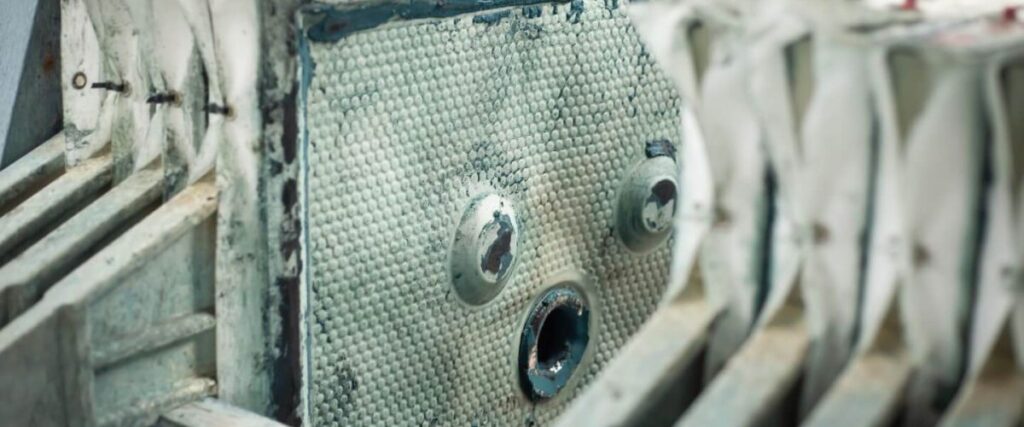

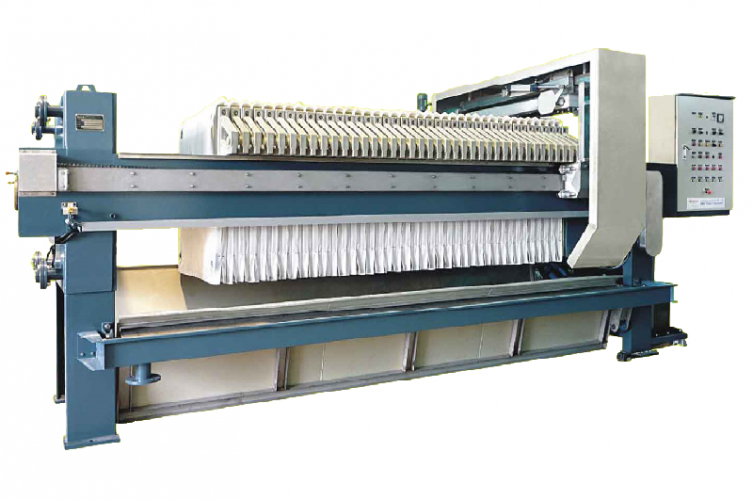

Understanding the Function of Filter Press Cloth

Filter press cloth is a key component in filter press systems. It acts as a porous barrier that allows liquid to pass through while retaining solid particles. The cloth’s intricate structure traps and holds solids while facilitating the flow of clarified liquid. This separation process is crucial in industries where solid-liquid separation is required for production or waste management purposes.

Materials and Types of Filter Press Cloth

Filter press cloth is available in different materials to suit various filtration needs. Common materials include:

- Polypropylene: Known for its excellent chemical resistance and high tensile strength, polypropylene filter press cloth is widely used in industries such as chemical processing, pharmaceuticals, and wastewater treatment.

- Polyester: Polyester filter press cloth offers good resistance to high temperatures and abrasive substances, making it suitable for applications in the mining, metallurgy, and food processing industries.

- Nylon: Nylon filter press cloth is valued for its high strength, durability, and resistance to most chemicals. It is commonly used in applications involving high-pressure filtration and abrasive slurries.

Applications of Filter Press Cloth

Filter press cloth finds extensive use in various industries, including:

- Chemical and Pharmaceutical: Filter press cloth is employed in chemical and pharmaceutical manufacturing for separating solids from liquids, such as in dewatering processes, catalyst recovery, or pharmaceutical product purification.

- Mining and Metallurgy: It is used in mining and metallurgical operations to extract valuable minerals and separate them from the ore slurry.

- Food and Beverage: Filter press cloth assists in the filtration of fruit juices, wine, beer, and edible oils, ensuring the removal of impurities and the production of high-quality consumables.

- Wastewater Treatment: Filter press cloth is integral to wastewater treatment plants, facilitating the removal of solids from wastewater streams before discharge.

- Industrial Processes: It is utilized in various industrial applications, including chemical filtration, paint and pigment production, and manufacturing processes that require the separation of solids from liquid streams.

[Conclusion]

In conclusion, a filter press cloth is an essential component in filtration systems, enabling efficient separation of solids from liquids. Its intricate structure and material properties play a vital role in optimizing filtration efficiency and ensuring the quality of filtered liquids.

By selecting the appropriate filter press cloth material and type for specific applications, industries can achieve reliable and consistent filtration results. Choose the power of filter press cloth to enhance productivity, improve product quality, and meet strict filtration requirements across diverse industrial sectors.