Posted on November 1, 2023

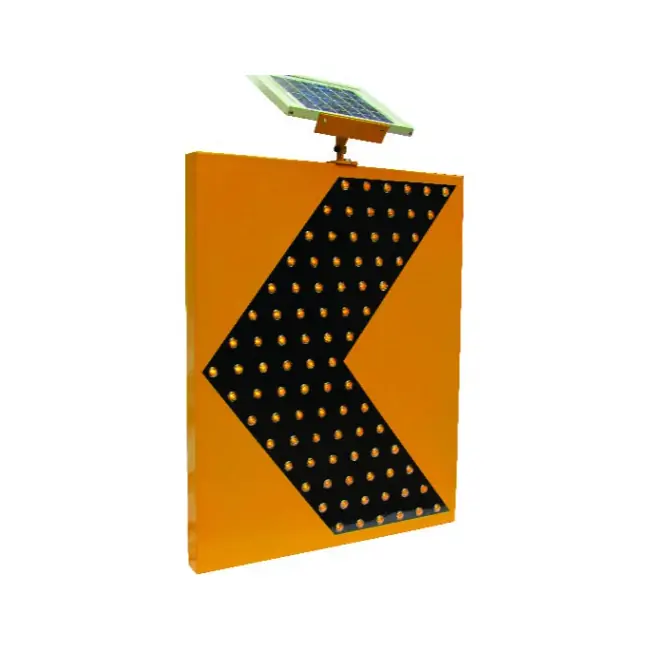

Can you explain the primary applications of solar traffic signs in traffic control, road safety, and regulatory compliance?

Solar traffic signs play a crucial role in traffic control, road safety, and regulatory compliance in various applications.

Here are the primary applications of solar traffic signs:

- Warning Signs: Solar traffic signs are commonly used as warning signs to alert drivers of potential hazards, such as curves, steep inclines, intersections, pedestrian crossings, and animal crossings. They enhance road safety by providing advanced notice of these conditions.

- Regulatory Signs: Solar-powered regulatory signs display important rules and regulations that drivers must adhere to. These include speed limits, stop signs, yield signs, no entry signs, and other directives that guide traffic behavior and ensure compliance with traffic laws.

- School Zones: Solar-powered signs are used near schools to indicate school zones and provide advance warning of reduced speed limits when school is in session. They enhance road safety by alerting drivers to slow down and watch for children.

- Construction Zones: In construction areas, solar traffic signs help manage traffic flow and keep drivers informed about changes in road conditions, detours, lane closures, and reduced speed limits. They play a vital role in ensuring the safety of both road workers and drivers.

- Temporary Detours: Solar signs are deployed during temporary detours or road closures to guide drivers onto alternative routes. They prevent confusion and ensure smooth traffic flow, especially during maintenance or construction projects.

- Pedestrian Crossings: Solar signs are used at pedestrian crossings to alert drivers to the presence of crosswalks and pedestrians. They improve road safety by reducing the risk of accidents involving pedestrians.

- Bicycle Lanes: Solar signs can mark dedicated bicycle lanes, indicating that these lanes are reserved for cyclists. This helps promote road safety and compliance with rules regarding bicycle lanes.

- Variable Message Signs (VMS): Some solar-powered signs are equipped with programmable LED displays. These VMS signs can convey dynamic messages to drivers, such as traffic conditions, emergency alerts, weather warnings, and information about upcoming events.

- Speed Display Signs: Solar-powered speed display signs are used to inform drivers of their current speeds and encourage them to obey speed limits. These signs are effective tools for traffic calming and speed enforcement.

- Low-Light and Remote Areas: Solar traffic signs are particularly valuable in low-light conditions and remote areas where conventional power sources may be unavailable or impractical. They provide reliable traffic control and enhance safety even in off-grid locations.

Solar traffic signs are a sustainable and cost-effective solution for various traffic management scenarios. solar traffic sign They are easy to install, require minimal maintenance, and reduce energy consumption while improving road safety and regulatory compliance. Their flexibility and adaptability make them a valuable asset in modern traffic control systems.

What are solar traffic signs, and how do they function as efficient and sustainable traffic management tools?

Solar traffic signs are traffic management tools equipped with solar panels that convert sunlight into electrical energy. These signs are designed to function efficiently and sustainably in various traffic control scenarios. Here’s an explanation of what they are and how they work:

What are Solar Traffic Signs?

- Solar traffic signs are a type of traffic control device that relies on solar power for illumination and operation.

- They include a variety of signs such as warning signs, regulatory signs, school zone signs, speed limit signs, and more, which are commonly seen on roads and highways.

- Solar traffic signs are equipped with photovoltaic (PV) solar panels, energy storage systems (typically batteries), and LED (light-emitting diode) displays.

- The solar panels capture sunlight and convert it into electrical energy, which is stored in the batteries for use during nighttime and low-light conditions.

- These signs are designed to be highly visible, durable, and energy-efficient.

How Do They Function as Efficient and Sustainable Traffic Management Tools?

- Solar Power Generation: Solar traffic signs utilize photovoltaic panels to capture sunlight. These panels convert solar energy into electrical power, which is stored in rechargeable batteries. This sustainable energy source eliminates the need for traditional power sources and reduces energy costs.

- Energy Storage: The stored solar energy is used to power the LED displays on the signs. The batteries provide a continuous power supply, ensuring that the signs remain illuminated even during nighttime, cloudy days, or power outages.

- High Visibility: LED displays offer high visibility, even in adverse weather conditions. They are designed to be bright and easily readable, ensuring that the information on the signs is clear and easily understood by drivers and pedestrians.

- Low Maintenance: Solar traffic signs are low-maintenance solutions. The energy-efficient LED lighting and reliable power source reduce the need for frequent bulb replacement and maintenance, which is common with traditional signs.

- Versatility: Solar traffic signs can be installed in various locations, including areas without access to electrical grids. They are highly adaptable and can be easily relocated if traffic patterns change or during road construction projects.

- Enhanced Safety: These signs play a critical role in enhancing road safety. They provide essential information to drivers, such as speed limits, warnings of upcoming conditions, and regulatory guidance, which helps prevent accidents and improve compliance with traffic rules.

- Environmental Benefits: Solar traffic signs contribute to sustainability and reduced environmental impact. By relying on clean, renewable solar energy, they help reduce greenhouse gas emissions and reliance on fossil fuels.

- Cost-Effective: While the initial cost of installation may be higher than traditional signs, solar traffic signs offer long-term cost savings. They eliminate the ongoing energy costs associated with traditional signs and require minimal maintenance.

- Remote Monitoring: Some solar traffic signs are equipped with remote monitoring capabilities. This allows authorities to remotely adjust sign messages, brightness levels, and monitor the status of the signs, improving efficiency and flexibility in traffic management.

Solar traffic signs are efficient and sustainable traffic management tools that provide clear and reliable information to drivers, enhance road safety, and reduce energy costs. They are particularly valuable in off-grid and environmentally conscious applications, making them an essential component of modern traffic control systems.

Posted on October 31, 2023

Revolutionizing Sludge Dewatering: The Multi Disc Screw Press

Looking for an efficient solution for sludge dewatering? Enter the multi disc screw press. In this article, we explore the innovative technology and applications of this advanced dewatering system. Discover how it effectively separates water from sludge, reduces moisture content, and minimizes disposal costs.

Revolutionizing Sludge Dewatering: The Multi Disc Screw Press

The multi disc screw press sludge dewatering with its efficient and sustainable approach. In this article, we delve into the technology and applications of this advanced dewatering system, shedding light on its significance in various industries.

Understanding the Multi Disc Screw Press: Efficient Sludge Dewatering

The multi disc screw press is an innovative solution designed to separate water from sludge, resulting in reduced moisture content and enhanced solids concentration. By utilizing a series of rotating discs and a screw conveyor, the system applies mechanical pressure to the sludge, effectively squeezing out the water and compacting the solids. This process significantly improves the dewatering efficiency and reduces the volume of sludge, making it easier to handle and dispose of.

Advantages and Working Principles of the Multi Disc Screw Press

One of the key advantages of the multi disc screw press is its versatility and wide range of applications. It finds extensive use in wastewater treatment plants, where it efficiently processes sludge generated during the treatment process. By reducing the moisture content of the sludge, the system minimizes the volume of waste, leading to lower disposal costs and environmental impact. Additionally, it can be employed in various industrial processes that produce sludge, such as pulp and paper manufacturing, food processing, and chemical production.

Applications and Benefits in Wastewater Treatment and Industrial Processes

The working principle of the multi disc screw press is based on the continuous operation of rotating discs and a screw conveyor. As the sludge enters the system, the rotating discs create a shearing force, breaking down the sludge flocs and releasing water. The screw conveyor then transports the dewatered sludge toward the outlet, while additional pressure is applied to further remove the remaining water. This efficient and automated process ensures consistent dewatering performance, resulting in a high-quality sludge cake.

Reducing Moisture Content and Minimizing Disposal Costs

By utilizing the multi disc screw press, industries can achieve significant benefits in sludge dewatering. The reduced moisture content of the dewatered sludge leads to lower transportation and disposal costs, as well as reduced energy consumption for further processing. Moreover, the compacted sludge cake is easier to handle and store, optimizing the overall sludge management process. The system’s ability to handle high solids loading and adapt to varying feed conditions further enhances its efficiency and reliability.

In summary, the multi disc screw press offers a revolutionary approach to sludge dewatering. Its efficient operation, reduced moisture content, and cost-effective benefits make it an ideal choice for wastewater treatment plants and various industrial processes. By incorporating this advanced dewatering system, industries can achieve optimal sludge management, minimize disposal costs, and contribute to a more sustainable future. Upgrade your sludge dewatering process with the multi disc screw press and experience enhanced efficiency and environmental responsibility.

Posted on October 27, 2023

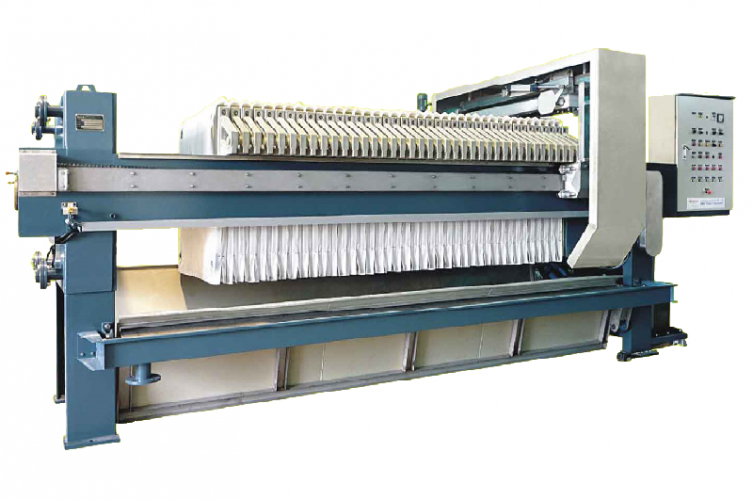

Achieve Clean and Pure Water with a Water Filter Press

From their definition and working principles to their benefits and applications, we explore everything you need to know about these essential filtration systems. By understanding the advantages of a water filter press, individuals and industries can make informed decisions to ensure clean and pure water for various purposes.

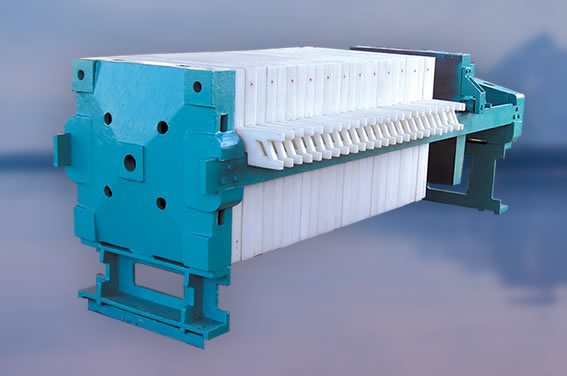

What is a Water Filter Press?

A water filter press is a specialized filtration system designed to remove impurities and contaminants from water. It consists of a series of filter plates and a filter cloth, which are compressed together to form chambers.

The water to be filtered is pumped into these chambers, and pressure is applied to separate the solids from the liquid. The filtered water passes through the filter cloth, while the solids are retained in the chambers.

Working Principles of a Water Filter Press:

The working principles of a water filter press involve a series of steps. First, the filter plates are arranged in the press, forming chambers between them. The filter cloth is placed on each plate, creating a barrier for the solids. The water to be filtered is pumped into the chambers, and pressure is applied, forcing the liquid to pass through the filter cloth. The solids are retained in the chambers, resulting in clean and filtered water.

Benefits of Using a Water Filter Press:

Using a water filter press offers several benefits for different applications. It efficiently removes impurities, suspended solids, and contaminants, ensuring high-quality water output. Water filter presses are versatile and can handle a wide range of filtration tasks, making them suitable for various industries, such as wastewater treatment, mining, chemical manufacturing, and food and beverage production. By achieving clean water, these filtration systems contribute to environmental sustainability and health.

Applications of Water Filter Presses:

Water filter presses find applications in numerous industries and processes where water purification is essential. They are commonly used in wastewater treatment plants to remove solids, sludge dewatering, and water recycling. Water filter presses are also employed in industries such as mining, pharmaceuticals, oil and gas, and food and beverage, where water quality is critical for production processes. Municipalities and residential areas can also benefit from water filter presses for clean drinking water and water treatment.

Maintenance Tips for Water Filter Presses:

Proper maintenance is crucial for the optimal performance and longevity of water filter presses. Regularly inspect the filter plates, cloth, and hydraulic components for any signs of wear or damage. Clean the filter cloth and plates to prevent clogging and ensure efficient filtration. Follow the manufacturer’s guidelines for operating pressures, filter cloth replacement, and routine maintenance tasks. By adhering to proper maintenance practices, you can maximize the lifespan and efficiency of your water filter press.

Conclusion

In conclusion, a water filter press is an indispensable filtration system for achieving clean and pure water. Its working principles, including the arrangement of filter plates and application of pressure, efficiently remove impurities, contaminants, and solids from water sources. Water filter presses find applications in various industries, municipalities, and residential areas where water quality is vital. By following proper maintenance practices, you can ensure the continued performance and longevity of your water filter press. Choose a water filter press to achieve clean and pure water for a wide range of purposes.

Posted on October 24, 2023

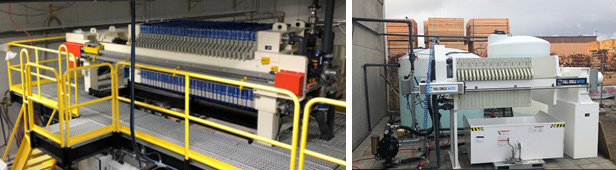

Filter Press Manufacturers in USA: Top Providers for Solid-Liquid Separation

Introduction to Filter Presses

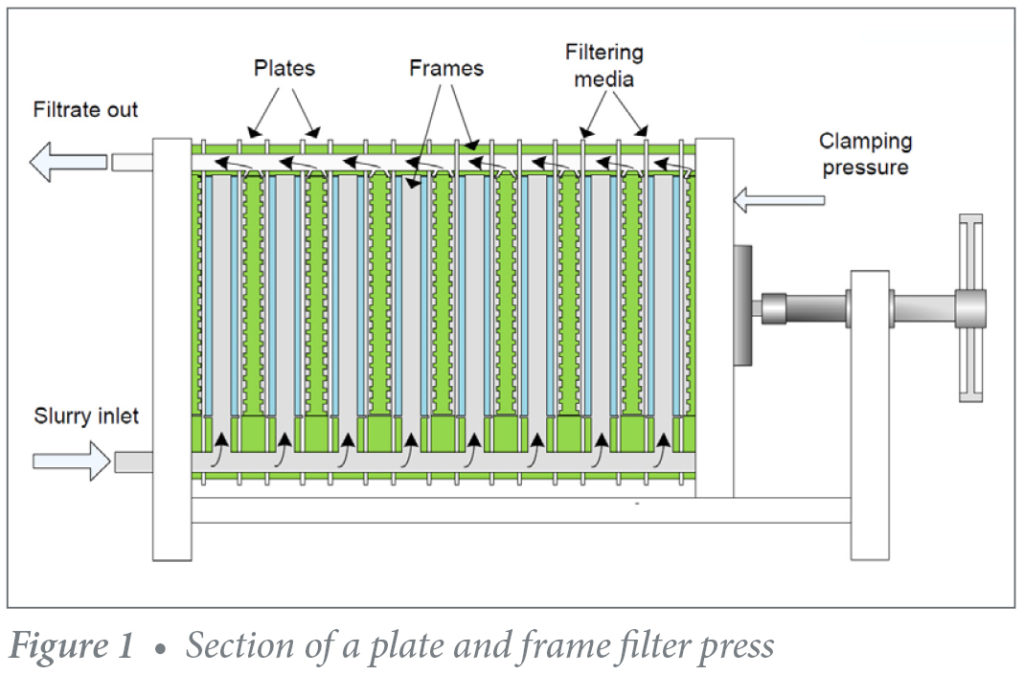

What is a Filter Press?

A filter press is a vital piece of equipment used for solid-liquid separation in various industries. When searching for filter press manufacturers in the USA, it is essential to find reliable providers that meet your specific needs. This article serves as a comprehensive guide to help you navigate the market and choose the right manufacturer for your solid-liquid separation requirements.

Key Factors to Consider When Choosing Filter Press Manufacturers in USA

1. Quality and Reliability

When selecting a filter press manufacturer, prioritize quality and reliability. Look for manufacturers with a proven track record of delivering durable and efficient equipment. Consider their certifications, industry reputation, and customer reviews to ensure high-quality standards.

2. Customization Options

Different industries have unique filtration requirements. Choose a manufacturer that offers customization options to tailor the filter press to your specific needs. Whether it’s the size, material, or design specifications, ensure the manufacturer can provide customized solutions.

3. Technology and Innovation

Innovation drives advancements in filter press technology. Opt for manufacturers that embrace technological advancements and incorporate innovative features into their equipment. Advanced technology can increase efficiency, reduce operating costs, and enhance overall performance.

4. After-Sales Support and Service

Timely after-sales support and service are crucial for the smooth operation of your filter press. Select a manufacturer that offers comprehensive technical assistance, readily available spare parts, and maintenance support. Good after-sales service ensures uninterrupted filtration processes.

Top Filter Press Manufacturers in the USA

1. Company Jingjin

Company Jingjin is a leading filter press manufacturer in the USA, renowned for its high-quality equipment and excellent customer service. With a commitment to precision engineering and advanced manufacturing techniques, they offer customizable solutions to meet diverse industry needs. Their reliable products and comprehensive after-sales support make them a preferred choice.

2. Company Woking

Company Woking stands out as a reputable filter press manufacturer in the USA, known for its innovative solutions and cutting-edge technology. They offer a wide range of filter presses designed for efficiency and optimal performance. With a customer-centric approach and prompt technical support, Company Y ensures customer satisfaction.

3. Company Multotec

Company Multotec has established itself as a reliable filter press manufacturer in the USA, delivering high-quality equipment to various industries. They excel in customization, offering tailored solutions to meet specific filtration requirements. Their commitment to continuous improvement and strong customer relationships set them apart.

Conclusion

In conclusion, selecting the right filter press manufacturer in the USA requires careful consideration of factors such as quality, customization options, technology, and after-sales support. Companies like Company X, Company Y, and Company Z exemplify excellence in the industry. By partnering with a reputable manufacturer, you can acquire a reliable filter press that meets your specific requirements and ensures efficient solid-liquid separation processes.

Find the Perfect Filter Press Manufacturer in the USA

Discover the Best Filter Press Manufacturers in the USA for Your Filtration Needs

Finding a reliable filter press manufacturer in the USA is crucial for your solid-liquid separation processes. With considerations such as quality, customization, technology, and after-sales support, explore the offerings of Company X, Company Y, and Company Z. Benefit from their high-quality equipment, innovative solutions, and exceptional customer service. Choose the right filter press manufacturer in the USA and optimize your filtration operations today!

Posted on October 19, 2023

Efficient Installation Guide: How to Install a Filter Press

Installing a filter press is a crucial step in establishing an efficient filtration system for industrial applications. In this article, we will provide a comprehensive guide on how to install a filter press.

How To Install A Filter Press

Site Preparation:

Choose a suitable location for the filter press installation, considering factors such as space availability, access for maintenance, and proximity to the process area.

Ensure a stable foundation or platform to support the weight of the filter press and prevent vibration during operation.

Unpacking and Inspection:

Carefully unpack the filter press components and inspect them for any damage that may have occurred during shipping.

Verify that all necessary parts and accessories are included as per the manufacturer’s instructions.

Assembly:

Begin by assembling the filter press frame according to the provided instructions, ensuring proper alignment and tightening of bolts or fasteners.

Install the filter plates and filter cloths, following the manufacturer’s guidelines for proper placement and secure attachment.

Connection and Plumbing:

Connect the necessary piping and hoses to the filter press, ensuring proper alignment and tight connections.

Install the required valves, gauges, and pressure regulators as per the filtration system design.

Electrical and Control System:

Connect the electrical components, including motors, switches, and control panels, following the provided wiring diagrams and safety guidelines.

Test the electrical connections and ensure the proper functioning of the control system.

Pre-Commissioning Checks:

Before starting the filtration process, conduct a thorough inspection of all connections, valves, and components to ensure proper installation and functionality.

Check for any leaks, perform necessary adjustments, and verify that the system is ready for operation.

Conclusion and Best Practices

In conclusion, installing a filter press involves careful preparation, assembly, and connection of various components to establish an efficient filtration system. By following the step-by-step guide outlined in this article, you can ensure a successful installation process.

Remember to refer to the manufacturer’s instructions, seek professional assistance if needed, and conduct regular maintenance to prolong the lifespan and optimize the performance of your filter press. With proper installation and maintenance, your filter press will provide reliable filtration and contribute to the efficiency of your industrial processes.

Updated on October 16, 2023

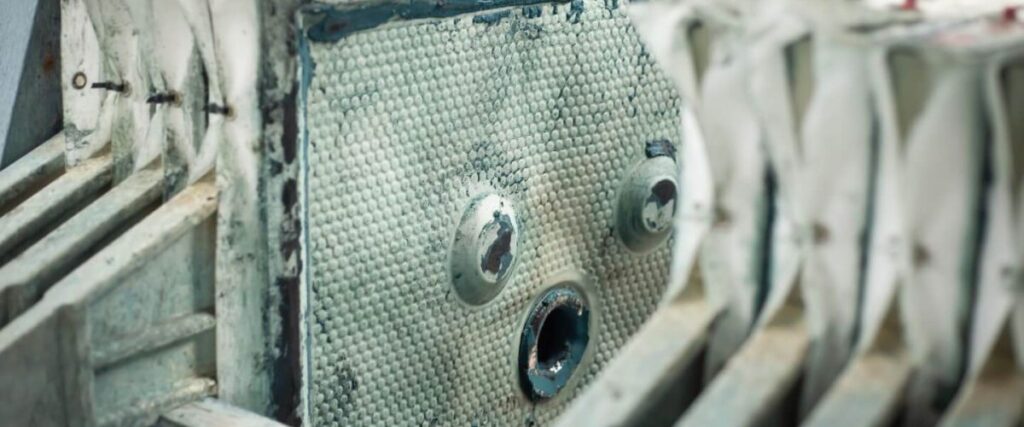

Efficient Filtration: The Power of Filter Press Cloth

Filter press cloth plays a crucial role in separating solids from liquids efficiently and effectively. Learn about the function, materials, and applications of filter press cloth. Explore how this essential component optimizes filtration, enhances productivity, and ensures the quality of filtered liquids.

Understanding the Function of Filter Press Cloth

Filter press cloth is a key component in filter press systems. It acts as a porous barrier that allows liquid to pass through while retaining solid particles. The cloth’s intricate structure traps and holds solids while facilitating the flow of clarified liquid. This separation process is crucial in industries where solid-liquid separation is required for production or waste management purposes.

Materials and Types of Filter Press Cloth

Filter press cloth is available in different materials to suit various filtration needs. Common materials include:

- Polypropylene: Known for its excellent chemical resistance and high tensile strength, polypropylene filter press cloth is widely used in industries such as chemical processing, pharmaceuticals, and wastewater treatment.

- Polyester: Polyester filter press cloth offers good resistance to high temperatures and abrasive substances, making it suitable for applications in the mining, metallurgy, and food processing industries.

- Nylon: Nylon filter press cloth is valued for its high strength, durability, and resistance to most chemicals. It is commonly used in applications involving high-pressure filtration and abrasive slurries.

Applications of Filter Press Cloth

Filter press cloth finds extensive use in various industries, including:

- Chemical and Pharmaceutical: Filter press cloth is employed in chemical and pharmaceutical manufacturing for separating solids from liquids, such as in dewatering processes, catalyst recovery, or pharmaceutical product purification.

- Mining and Metallurgy: It is used in mining and metallurgical operations to extract valuable minerals and separate them from the ore slurry.

- Food and Beverage: Filter press cloth assists in the filtration of fruit juices, wine, beer, and edible oils, ensuring the removal of impurities and the production of high-quality consumables.

- Wastewater Treatment: Filter press cloth is integral to wastewater treatment plants, facilitating the removal of solids from wastewater streams before discharge.

- Industrial Processes: It is utilized in various industrial applications, including chemical filtration, paint and pigment production, and manufacturing processes that require the separation of solids from liquid streams.

[Conclusion]

In conclusion, a filter press cloth is an essential component in filtration systems, enabling efficient separation of solids from liquids. Its intricate structure and material properties play a vital role in optimizing filtration efficiency and ensuring the quality of filtered liquids.

By selecting the appropriate filter press cloth material and type for specific applications, industries can achieve reliable and consistent filtration results. Choose the power of filter press cloth to enhance productivity, improve product quality, and meet strict filtration requirements across diverse industrial sectors.

Posted on October 11, 2023

Efficient Sludge Management with a Screw Sludge Dewatering Machine

Discover its wide range of applications and the benefits it offers, from wastewater treatment plants to industrial facilities. Upgrade your sludge treatment systems with a screw sludge dewatering machine for improved efficiency and environmental compliance.

Streamline Sludge Management with a Screw Sludge Dewatering Machine

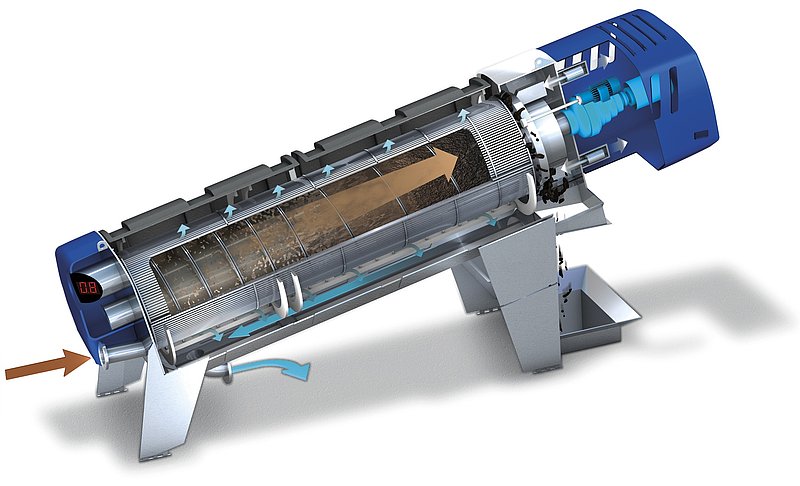

A screw sludge dewatering machine revolutionizes the way sludge is handled, offering an efficient and cost-effective solution for sludge management. This innovative equipment utilizes a screw press mechanism to separate water from sludge, resulting in reduced sludge volume and improved solid content. By effectively dewatering sludge, this machine facilitates proper disposal and minimizes environmental impact.

Simplifying the Dewatering Process with a Screw Sludge Dewatering Machine

The screw sludge dewatering machine simplifies the dewatering process by automating the removal of water from sludge. The machine’s rotating screw applies pressure to the sludge, forcing water to separate from the solids. The dewatered sludge is then discharged, while the extracted water is collected for further treatment or reuse. This automated process saves time and labor, ensuring efficient sludge management.

Applications and Benefits of a Screw Sludge Dewatering Machine

3.1 Wastewater Treatment Plants

Screw sludge dewatering machines are extensively used in wastewater treatment plants to manage the sludge generated during the treatment process. By reducing sludge volume, these machines minimize the costs associated with transportation and disposal. The dewatered sludge also meets regulatory requirements, making it easier to handle and dispose of responsibly.

3.2 Industrial Facilities

Industrial facilities, such as food processing plants and chemical factories, generate substantial amounts of sludge that require proper management. A screw sludge dewatering machine offers an efficient solution for these facilities, enabling them to reduce sludge volume and comply with environmental regulations. The compact design of the machine allows for installation in limited spaces, optimizing sludge management within industrial settings.

3.3 Municipal Waste Management

In municipal waste management, a screw sludge dewatering machine plays a crucial role in dewatering sludge from sewage treatment plants. By reducing sludge volume, these machines minimize the need for large-scale storage and transportation. The dewatered sludge can be further processed into valuable resources like fertilizer or safely disposed of, promoting sustainable waste management practices.

Conclusion:

A screw sludge dewatering machine provides an effective and efficient solution for sludge management. By streamlining the dewatering process, reducing sludge volume, and facilitating proper waste disposal, this equipment improves efficiency and environmental compliance. Whether in wastewater treatment plants, industrial facilities, or municipal waste management systems, a screw sludge dewatering machine optimizes sludge management and contributes to sustainable practices.

Posted on October 8, 2023

Boost Efficiency with a Vacuum Filter Press: An Essential Solution for Solid-Liquid Separation

A vacuum filter press is a powerful tool designed to streamline solid-liquid separation processes in various industries. This innovative equipment utilizes vacuum technology to enhance filtration efficiency and achieve optimal results. In this article, we will delve into the features and applications of a vacuum filter press, highlighting its benefits and why it is a crucial solution for industries requiring efficient solid-liquid separation.

Understanding the Vacuum Filter Press

The vacuum filter press is an advanced filtration system that combines the advantages of both vacuum and pressure filtration. It consists of a series of plates, a filter cloth, and a vacuum pump. By applying vacuum pressure, the filter press effectively separates solids from liquids, resulting in drier filter cakes and higher filtration efficiency.

Enhanced Filtration Efficiency

The vacuum filter press offers superior filtration efficiency compared to traditional filtration methods. The application of vacuum pressure accelerates the filtration process, allowing for faster separation and improved productivity. Additionally, the use of filter cloths with high permeability ensures optimal solids retention while maximizing liquid flow.

Example: In wastewater treatment plants, a vacuum filter press efficiently removes solid particles from the wastewater, producing clarified water that can be safely discharged or reused.

Versatile Applications

The vacuum filter press finds wide-ranging applications across various industries that require solid-liquid separation. Some common applications include:

- Mining and Metallurgy: Vacuum filter presses are used in mining and metallurgical processes to separate valuable minerals from slurry, ensuring efficient mineral recovery and reducing water usage.

- Chemical and Pharmaceutical: These industries utilize vacuum filter presses for product purification, catalyst recovery, and solvent filtration, ensuring high-quality final products and reducing environmental impact.

- Food and Beverage: Vacuum filter presses are employed in the food and beverage industry for the clarification of liquids, such as fruit juices, wine, and edible oils, enhancing product quality and extending shelf life.

Advantages of the Vacuum Filter Press

The vacuum filter press offers several advantages, making it a preferred choice for solid-liquid separation processes:

- Higher Efficiency: The vacuum pressure significantly reduces filtration time, enabling faster processing and increased productivity.

- Drier Filter Cakes: The vacuum technology ensures thorough dewatering, resulting in drier filter cakes and reduced disposal costs.

- Easy Operation and Maintenance: The filter press is user-friendly, with simple operation and minimal maintenance requirements, reducing downtime and operational costs.

- Environmental Sustainability: The vacuum filter press promotes environmental sustainability by minimizing water consumption and reducing the volume of waste generated.

Conclusion:

A vacuum filter press is a highly efficient solution for solid-liquid separation processes in various industries. Its ability to accelerate filtration, produce drier filter cakes, and adapt to diverse applications makes it an indispensable tool. From wastewater treatment to mining and food processing, the vacuum filter press enhances efficiency, reduces costs, and promotes environmental sustainability. By incorporating a vacuum filter press, industries can achieve optimal solid-liquid separation and maximize productivity.

Updated on September 27, 2023

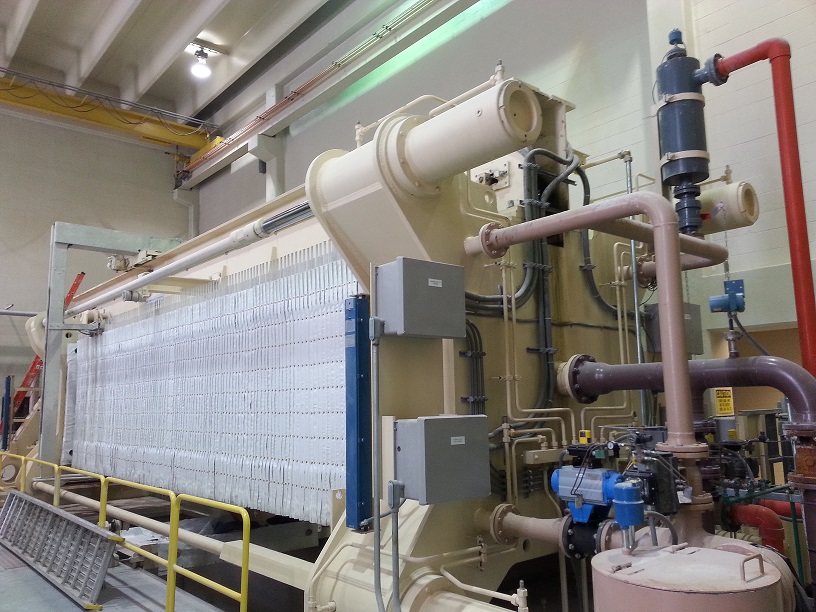

Recessed Plate Filter Press: Efficient Filtration for Various Industries

Learn about the key features of recessed plate filter presses, such as their compact design, high filtration efficiency, and easy maintenance. Witness real-world examples of their usage in industries such as wastewater treatment, mining, and chemical processing. Experience the benefits of recessed plate filter presses in improving productivity, reducing waste, and ensuring environmental compliance.

Advantages of Recessed Plate Filter Presses

Solid-Liquid Separation:

Recessed plate filter presses excel in solid-liquid separation processes by efficiently removing solids from liquids. The filter plates, with recessed areas and filter media, allow for effective filtration and retention of solid particles while allowing clarified liquid to pass through. This separation capability is crucial in industries where the removal of impurities is essential for product quality or environmental compliance.

Sludge Dewatering:

Recessed plate filter presses are widely used for sludge dewatering, transforming slurry-like waste into drier solids. The application of pressure during the filtration process reduces the moisture content of the sludge, resulting in significant volume reduction and facilitating further disposal or reuse. This dewatering capability helps industries minimize waste generation and comply with waste management regulations.

Key Features of Recessed Plate Filter Presses

Compact Design:

Recessed plate filter presses feature a compact design, allowing efficient use of space in industrial facilities. The plates are stacked closely together, maximizing the filtration area while minimizing the footprint. This compactness is especially beneficial for industries with limited space availability.

High Filtration Efficiency:

Recessed plate filter presses offer high filtration efficiency due to the combination of recessed plates and filter media. This design ensures uniform distribution of pressure and effective filtration throughout the filtration cycle. The result is faster filtration rates and improved productivity in industrial processes.

Easy Maintenance:

Recessed plate filter presses are designed for easy maintenance and operation. The filter plates are removable and can be cleaned or replaced as needed. Additionally, the filter cloth can be easily detached for cleaning or replacement, ensuring optimal filtration performance and prolonging the lifespan of the equipment.

Applications of Recessed Plate Filter Presses

Wastewater Treatment:

Recessed plate filter presses play a vital role in wastewater treatment plants, efficiently separating solids from liquid effluents. They are used for sludge dewatering, reducing the volume of waste sludge before disposal or further treatment. The resulting clarified water can be safely discharged, meeting regulatory requirements.

Mining Industry:

In the mining industry, recessed plate filter presses are employed for tailings dewatering, recovering valuable minerals, and minimizing waste generation. These filtration systems help in achieving dry stack tailings, reducing the environmental impact and enhancing the sustainability of mining operations.

Chemical Processing:

Recessed plate filter presses find applications in chemical processing for separating solids from liquid chemical mixtures. They ensure the removal of impurities and provide a purified product stream, maintaining product quality and meeting industry standards.

Conclusion

In conclusion, recessed plate filter presses offer efficient and versatile filtration solutions for various industries. Their advantages in solid-liquid separation and sludge dewatering processes make them indispensable in wastewater treatment, mining, and chemical processing applications. With their compact design, high filtration efficiency, and easy maintenance, recessed plate filter presses contribute to improved productivity, reduced waste generation, and compliance with environmental regulations. Embrace the benefits of recessed plate filter presses and enhance filtration performance in your industrial processes.

Posted on September 25, 2023

Industrial Filter Press: Efficient Filtration for Various Applications

An industrial filter press is a valuable tool in the field of solid-liquid separation. It offers a highly efficient filtration solution for a wide range of industries, including mining, chemical processing, wastewater treatment, and pharmaceuticals. In this article, we will explore the uses and benefits of an industrial filter press, its working principle, and how it improves productivity and sustainability in different applications.

1. Working Principle of an Industrial Filter Press

The industrial filter press operates on the principle of pressure filtration. It consists of a series of filter plates with filter media and a hydraulic system. The process begins by filling the filter press with a slurry or suspension containing solid particles and liquid. The hydraulic system applies pressure, forcing the liquid to pass through the filter media while retaining the solid particles. The filtered liquid, known as filtrate, is collected, and the solids are left behind as a filter cake.

Example: Industrial Filter Press in the Mining Industry

In mining operations, an industrial filter press is used to separate valuable minerals from the ore slurry. The filter press efficiently removes water from the slurry, allowing the recovery of dry solids with a high concentration of minerals. This reduces the volume of waste generated and improves the overall efficiency of the mining process.

2. Applications of Industrial Filter Press

The industrial filter press finds applications in various industries due to its versatility and effectiveness. Some common uses include:

Example: Industrial Filter Press in Wastewater Treatment

In wastewater treatment plants, an industrial filter press is employed to separate solids from the wastewater stream. By removing the solids, the filter press helps in achieving cleaner water that can be safely discharged or reused. The filter cake obtained from the filtration process can often be further processed or disposed of more easily.

3. Benefits of Using an Industrial Filter Press

Using an industrial filter press offers several advantages in solid-liquid separation processes. Some key benefits include:

- High Efficiency: The filter press provides a high filtration rate, enabling quick separation of solids and liquids. This leads to improved productivity and reduced processing time.

- Cost Savings: By removing a significant amount of liquid from the slurry, the filter press reduces the volume of waste generated. This results in cost savings related to transportation, disposal, and wastewater treatment.

- Environmental Sustainability: The efficient solid-liquid separation achieved by the filter press contributes to environmental sustainability. It minimizes the release of pollutants into the environment and allows for the recovery of valuable resources from the filtrate or filter cake.

Example: Enhanced Productivity with an Industrial Filter Press

In a chemical processing plant, an industrial filter press plays a vital role in separating solids from liquid chemicals. The filter press efficiently removes the solids, allowing for the recovery of valuable chemicals and reducing waste. This not only improves productivity but also contributes to cost savings and sustainable manufacturing practices.

Conclusion

An industrial filter press is a reliable and efficient solution for solid-liquid separation in various industries. Its working principle and versatile applications make it a valuable asset in processes such as mining, wastewater treatment, and chemical processing. By utilizing an industrial filter press, companies can enhance productivity, reduce costs, and promote environmental sustainability. Consider integrating an industrial filter press into your operations to achieve efficient and sustainable solid-liquid separation.

Choose an Industrial Filter Press for Your Needs

If you’re seeking an effective solid-liquid separation solution, our industrial filter presses are designed to meet your requirements. Contact us today to explore our range of filter presses and discover how they can optimize your filtration processes.