Posted on February 1, 2024

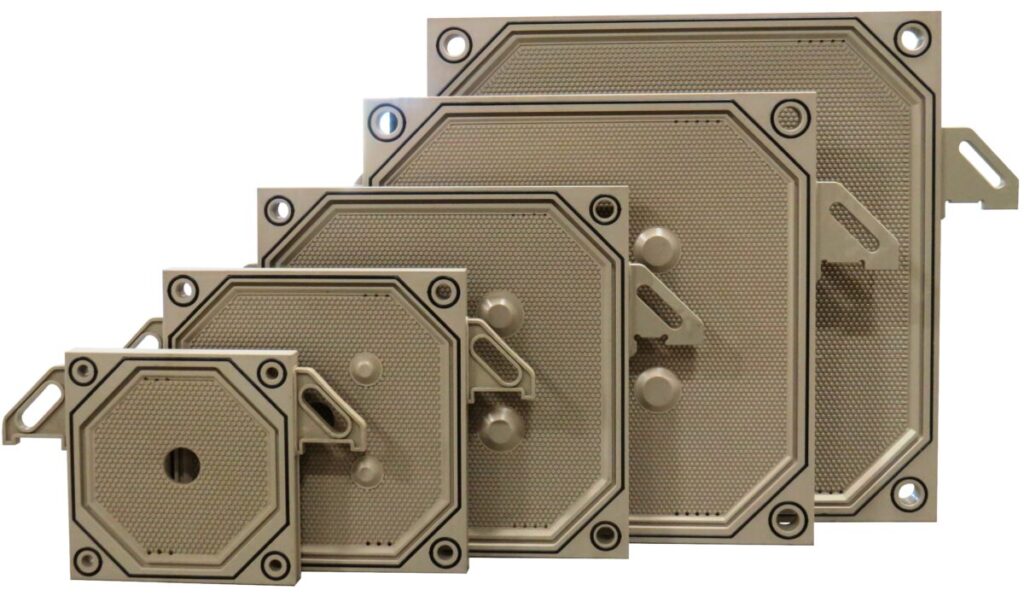

What are Filter Press Plates?

Filter press plates are an essential component in various industrial applications, including wastewater treatment, chemical processing, and food and beverage production. They are used to separate solids from liquids, and their efficiency and effectiveness play a crucial role in ensuring the quality of the final product. In this article, we will explore the definition, types, and benefits of filter press plates, as well as their applications and maintenance requirements.

Definition and Types of Filter Press Plates

Filter press plates are flat, rectangular plates with a series of holes or apertures that are used to filter out impurities from a liquid. They are typically made of materials such as stainless steel, aluminum, or polypropylene, which are resistant to corrosion and wear. There are several types of filter press plates available, including:

- Chamber filter press plates: These plates are designed for use in chamber filter presses, which are commonly used in wastewater treatment and chemical processing applications.

- Membrane filter press plates: These plates are designed for use in membrane filter presses, which are used in applications that require a high level of filtration accuracy, such as in the food and beverage industry.

- Plate and frame filter press plates: These plates are designed for use in plate and frame filter presses, which are commonly used in various industrial applications, including wastewater treatment and chemical processing.

Benefits of Filter Press Plates

Filter press plates offer several benefits, including:

- High filtration efficiency: Filter press plates are designed to filter out impurities from a liquid, resulting in a high-quality filtrate.

- Durability: Filter press plates are made of materials that are resistant to corrosion and wear, ensuring a long lifespan and reducing the need for frequent replacements.

- Versatility: Filter press plates can be used in a variety of applications, including wastewater treatment, chemical processing, and food and beverage production.

- Cost-effectiveness: Filter press plates are a cost-effective solution for separating solids from liquids, as they require minimal energy and maintenance.

Applications of Filter Press Plates

Filter press plates are used in a variety of applications, including:

- Wastewater treatment: Filter press plates are used to remove impurities from wastewater, such as suspended solids, bacteria, and viruses, before it is discharged into the environment.

- Chemical processing: Filter press plates are used to separate solids from liquids in chemical processing applications, such as in the production of chemicals, pharmaceuticals, and fuels.

- Food and beverage production: Filter press plates are used to remove impurities from liquids in the food and beverage industry, such as in the production of juice, wine, and dairy products.

- Biotechnology: Filter press plates are used in biotechnology applications, such as in the production of biopharmaceuticals and biodiesel.

Maintenance of Filter Press Plates

To ensure the optimal performance of filter press plates, regular maintenance is required. This includes:

- Cleaning: Filter press plates should be cleaned regularly to remove any impurities that may have accumulated during use.

- Inspection: Filter press plates should be inspected regularly for any signs of wear or damage, and replaced as needed.

- Lubrication: Filter press plates should be lubricated regularly to ensure smooth operation and reduce wear.

In conclusion, filter press plates are an essential component in various industrial applications, offering high filtration efficiency, durability, versatility, and cost-effectiveness. By understanding the definition, types, benefits, and applications of filter press plates, as well as their maintenance requirements, industries can optimize their use and improve their overall efficiency.