Posted on February 21, 2024

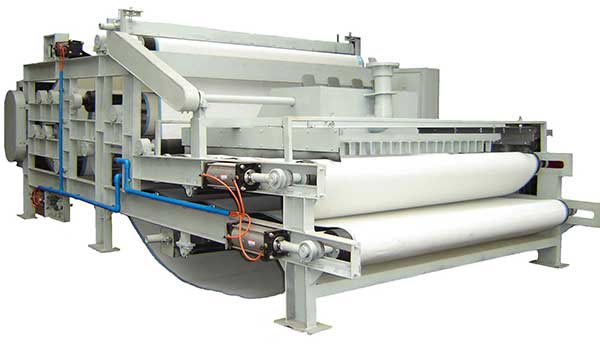

What is Belt Press Dewatering?

Belt press dewatering is a process used to remove excess water from solids, such as sludge or slurry, by applying pressure to the material through a series of rollers or belts. This process is commonly used in various industries, including wastewater treatment, mining, and agriculture, to name a few. In this article, we will explore the belt press dewatering process in detail, including its principles, types, and applications.

Principle of Belt Press Dewatering

The belt press dewatering process is based on the principle of pressure filtration. The material to be dewatered is placed on a permeable belt or screen, which is then passed through a series of rollers or belts. The rollers or belts apply pressure to the material, causing the water to be squeezed out of the material and collected in a separate container. The pressure applied to the material can be adjusted to achieve the desired level of dewatering.

Types of Belt Press Dewatering

There are several types of belt press dewatering systems available, including:

- Gravity Belt Press: This is the most common type of belt press dewatering system, which uses gravity to help remove water from the material.

- Inclined Belt Press: This type of system is similar to the gravity belt press, but the belt is inclined at an angle to improve the dewatering process.

- Wedge Belt Press: This type of system uses a wedge-shaped belt to apply pressure to the material, which helps to remove more water than traditional belt press systems.

- Plate and Frame Belt Press: This type of system uses a series of plates and frames to apply pressure to the material, which helps to remove water and also separate solids from liquids.

Applications of Belt Press Dewatering

Belt press dewatering has a wide range of applications across various industries, including:

- Wastewater Treatment: Belt press dewatering is commonly used in wastewater treatment plants to remove excess water from sludge, which can then be used as fertilizer or disposed of safely.

- Mining: Belt press dewatering is used in the mining industry to remove water from mineral concentrates, such as iron ore and coal, which helps to increase their weight and value.

- Agriculture: Belt press dewatering is used in agriculture to remove excess water from the soil, which helps to improve soil quality and reduce the risk of waterlogging.

- Food Processing: Belt press dewatering is used in the food processing industry to remove excess water from food products, such as fruits and vegetables, which helps to improve their shelf life and quality.

Advantages of Belt Press Dewatering

Belt press dewatering has several advantages over other dewatering methods, including:

- Cost-Effective: Belt press dewatering is a cost-effective method compared to other dewatering methods, such as centrifugation or filtration.

- Easy to Operate: Belt press dewatering is relatively easy to operate and maintain, as it requires minimal labor and equipment.

- Flexible: Belt press dewatering can be used to dewater a wide range of materials, including sludge, slurry, and solids.

- High Efficiency: Belt press dewatering is a highly efficient method, as it can remove up to 90% of water from the material.

Conclusion

In conclusion, belt press dewatering is a widely used process in various industries for removing excess water from solids. The process is based on the principle of pressure filtration and has several types, including gravity, inclined wedge, and plate and frame belt presses. Belt press dewatering has several advantages, including cost-effectiveness, ease of operation, flexibility, and high efficiency. By understanding the belt press dewatering process and its applications, industries can optimize their dewatering methods and improve their overall efficiency.

Category: Blog Tags: belt press dewatering