Posted on December 13, 2023

Plate and Frame Filter Press: The Ultimate Solution for Filtering Applications

Are you looking for an efficient and effective filtration solution for your industrial or commercial applications? Look no further than the plate and frame filter press!

What is a Plate and Frame Filter Press?

A plate and frame filter press is a type of filter press that uses a plate and frame design to separate solids from liquids. The press consists of a plate and frame, which are filled with a filter medium.

And a hydraulic system that applies pressure to the filter medium. The plate and frame design provides a large surface area for filtration, making it ideal for high-volume filtration applications.

Benefits of Plate and Frame Filter Presses

Plate and frame filter presses offer several benefits over other types of filter presses, including:

- High-volume filtration: Plate and frame filter presses are capable of filtering large volumes of liquid, making them ideal for industrial and commercial applications.

- Efficient separation: The plate and frame design provides a large surface area for filtration, resulting in efficient separation of solids from liquids.

- Low maintenance: Plate and frame filter presses are relatively easy to maintain and clean, reducing downtime and maintenance costs.

- Versatility: Plate and frame filter presses can be used in a variety of industries, including chemical, food and beverage, and pharmaceutical.

Applications of Plate and Frame Filter Presses

Plate and frame filter presses have a wide range of applications in various industries, including:

- Chemical processing: Plate and frame filter presses are used to remove impurities from chemical processes, such as caustic soda and sulfuric acid.

- Food and beverage: Plate and frame filter presses are used to remove impurities from food and beverage products, such as coffee and tea.

- Pharmaceutical: Plate and frame filter presses are used to remove impurities from pharmaceutical products, such as tablets and capsules.

How Plate and Frame Filter Presses Work

The plate and frame filter press works by applying pressure to the filter medium, causing the solids to separate from the liquid. The process involves the following steps:

- The filter medium is filled into the plate and frame.

- The liquid to be filtered is poured into the plate and frame.

- The hydraulic system applies pressure to the filter medium, causing the solids to separate from the liquid.

- The filtered liquid is collected, while the solids are discharged.

Types of Plate and Frame Filter Presses

There are several types of plate and frame filter presses available, including:

- Horizontal plate and frame filter press: These are the most common types of plate and frame filter press and are used in a variety of industries.

- Vertical plate and frame filter press: These are ideal for small-scale filtration applications and are commonly used in laboratory settings.

- Central frame plate and frame filter press: These are used in high-volume filtration applications, and feature a central frame that provides additional support and stability.

Conclusion

In conclusion, the plate and frame filter press is an efficient and effective filtration solution for a wide range of industrial and commercial applications. With its high-volume filtration capabilities, efficient separation, and low maintenance requirements.

It is an essential piece of equipment for any business that requires filtration solutions. Whether you are in the chemical, food, beverage, or pharmaceutical industry, the plate and frame filter press is the perfect solution for all your filtration needs.

Posted on December 12, 2023

Belt Conveyor Supplier: Efficient and Reliable Conveyance Solutions

Jingjin manufacturer is a reliable belt conveyor supplier that offers customizable solutions to meet your specific needs. Our products are high-quality, efficient, and cost-effective, and we have years of experience in the conveyor industry. Contact us today to learn more about our products and services.

Belt Conveyor Supplier – Efficient and Reliable Conveyance Solutions

Looking for a reliable belt conveyor supplier that can meet your industrial needs? Look no further than Jingjin manufacturer. As a leading belt conveyor supplier, we offer a wide range of conveyance solutions designed to increase efficiency, productivity, and safety in various industries.

Advantages of Choosing Belt Conveyor Supplier

Several reasons make Jingjin Manufacturer the best belt conveyor supplier in the market:

- High-quality products: Our belt conveyors are made from durable materials that ensure maximum durability and longevity.

- Customizable solutions: We offer customizable conveyor solutions to meet your specific needs and requirements.

- Efficient operation: Our belt conveyors are designed to operate efficiently, reducing downtime and increasing productivity.

- Cost-effective: Our conveyor solutions are cost-effective, providing value for your money.

Applications of Belt Conveyor Supplier

Our belt conveyors can be used in various industries, including:

- Manufacturing: Belt conveyors are used to transport raw materials, finished products, and other materials within a manufacturing facility.

- Logistics: Belt conveyors are used to move goods and products efficiently within a warehouse or distribution center.

- Construction: Belt conveyors are used to transport building materials, tools, and other equipment on construction sites.

Why Choose Belt Conveyor Supplier from [Company Name]?

There are several reasons to choose Jingjin Manufacturer as your belt conveyor supplier:

- Experience: We have years of experience in the conveyor industry, providing high-quality products and solutions.

- Innovation: We continuously innovate and improve our products to meet the changing needs of our customers.

- Customer service: We provide excellent customer service and support to ensure your complete satisfaction.

Conclusion

In conclusion, Jingjin Manufacturer is the leading belt conveyor supplier in the market, offering efficient, reliable, and cost-effective conveyance solutions. Contact us today to learn more about our products and services and how we can help improve your industrial operations.

Posted on December 6, 2023

What is a Membrane Filter Press?

Membrane filter presses are a revolutionary solution for liquid filtration, offering a range of benefits over traditional filter presses. In this article, we will explore the basics of membrane filter presses, their advantages, and how they can be used in various industries.

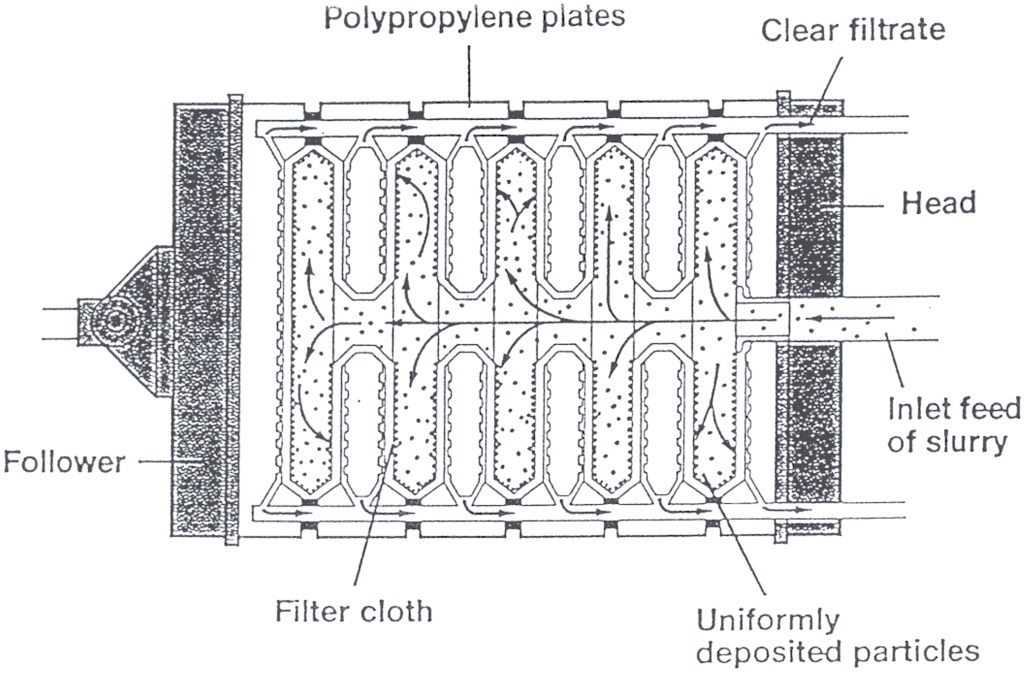

How Does a Membrane Filter Press Work?

A membrane filter press is a type of filter that uses a semi-permeable membrane to separate solids from liquids. The membrane is made up of tiny pores that allow liquid to pass through while retaining solids and other impurities. The process involves applying pressure to the liquid, forcing it through the membrane, and collecting the filtered liquid on one side of the membrane.

Advantages of Membrane Filter Presses

Membrane filter presses offer several advantages over traditional filter presses, including:

- Higher filtration efficiency: Membrane filter presses can filter out smaller particles and impurities, resulting in a higher-quality filtrate.

- Lower operational costs: Membrane filter presses require less maintenance and energy than traditional filter presses, leading to lower operational costs.

- Faster filtration: Membrane filter presses can filter liquids faster than traditional filter presses, resulting in shorter processing times.

- Improved product quality: Membrane filter presses can help improve the quality of products by removing impurities and contaminants.

Applications of Membrane Filter Presses

Membrane filter presses have a wide range of applications in various industries, including:

- Chemical processing: Membrane filter presses are used to filter chemicals and remove impurities, improving the quality of the final product.

- Food and beverage: Membrane filter presses are used to filter liquids and remove impurities, improving the quality of food and beverages.

- Pharmaceutical: Membrane filter presses are used to filter pharmaceutical liquids and remove impurities, improving the quality of the final product.

- Wastewater treatment: Membrane filter presses are used to remove impurities and contaminants from wastewater, improving the quality of the water.

Examples of Membrane Filter Presses

Some examples of membrane filter presses include:

- Microfiltration: used for the filtration of small particles and impurities from liquids.

- Ultrafiltration: used for the filtration of larger particles and impurities from liquids.

- Nanofiltration: used for the filtration of very small particles and impurities from liquids.

Conclusion

Membrane filter presses are a revolutionary solution for liquid filtration, offering a range of benefits over traditional filter presses. With their high filtration efficiency, lower operational costs, faster filtration, and improved product quality.

Membrane filter presses are an ideal choice for a variety of industries. By understanding how these presses work and their applications, businesses can make informed decisions about incorporating membrane filter presses into their operations.

Posted on November 30, 2023

Belt Press Machine for Efficient Sludge Dewatering

Sludge dewatering is a critical process in various industries, including wastewater treatment, chemical processing, and food processing. One of the most efficient methods for sludge dewatering is using a belt press machine.

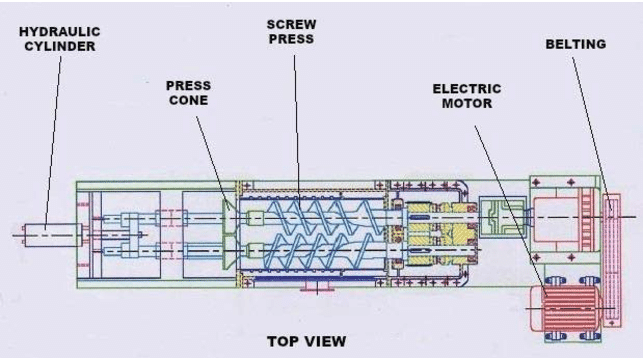

What is a Belt Press Machine?

A belt press machine is a type of equipment used for sludge dewatering. It consists of a series of rollers and belts that work together to remove excess water from the sludge. The machine is designed to optimize the dewatering process, reducing the amount of water in the sludge and increasing its solid content.

How Does a Belt Press Machine Work?

The belt press machine works by passing the sludge through a series of rollers and belts. The rollers apply pressure to the sludge, causing the water to be squeezed out. The belts then take the dewatered sludge and press it further, removing any remaining water. The resulting product is a dry, solid sludge that can be easily disposed of or further processed.

Benefits of Belt Press Machines

Belt press machines offer several benefits for sludge dewatering, including:

- Efficient Dewatering: Belt press machines are highly efficient in removing water from sludge, resulting in a dry, solid product.

- Compact Design: Belt press machines are designed to be compact and space-saving, making them ideal for use in small facilities.

- Easy Operation: Belt press machines are easy to operate and maintain, requiring minimal personnel and training.

- Cost-Effective: Belt press machines are a cost-effective solution for sludge dewatering, reducing the amount of water that needs to be disposed of and saving on disposal costs.

Features of Belt Press Machines

Belt press machines are designed with several features that enhance their efficiency and effectiveness, including:

- Adjustable Pressure: The pressure applied by the rollers and belts can be adjusted to suit different types of sludge and dewatering requirements.

- Multiple Rollers: The use of multiple rollers allows for a higher dewatering efficiency, as the sludge is pressed multiple times.

- Automatic Control: Many belt press machines are equipped with automatic control systems, allowing for easy operation and monitoring.

- Customizable Design: Belt press machines can be customized to meet specific dewatering requirements, including the ability to adjust the size and number of rollers and belts.

Examples of Belt Press Machine Applications

Belt press machines are used in a variety of industries for sludge dewatering, including:

- Wastewater Treatment: Belt press machines are commonly used in wastewater treatment plants to dewater sludge before disposal.

- Chemical Processing: Belt press machines are used in chemical processing plants to dewater sludge generated during production.

- Food Processing: Belt press machines are used in food processing plants to dewater sludge generated during food production.

Conclusion

Belt press machines are an efficient and cost-effective solution for sludge dewatering. Their compact design, easy operation, and adjustable pressure make them ideal for use in a variety of industries. By using a belt press machine, industries can reduce the amount of water in their sludge and dispose of it more easily, saving on disposal costs and improving the environment.

FAQs

- What is the difference between a belt press machine and a plate press machine?

A belt press machine uses belts and rollers to dewater sludge, while a plate press machine uses a plate and a pressure system to dewater sludge. - What are the benefits of using a belt press machine?

Belt press machines are efficient, compact, easy to operate, and cost-effective. - What industries use belt press machines for sludge dewatering?

Wastewater treatment, chemical processing, and food processing industries commonly use belt press machines for sludge dewatering.

Posted on November 24, 2023

How Does a Filter Press Work?

Are you curious about how a filter press works? Look no further! In this article, we will provide a comprehensive guide on the basics of filter presses, including their design, operation, and benefits. Whether you’re a seasoned professional or just starting out.

Filter Press Design and Construction

A filter press is a type of fluid press that is used to separate liquids and solids. The basic design consists of a plunger, a filter cloth, and a housing. The plunger is used to apply pressure to the filter cloth, causing the liquid to pass through the cloth and leave behind the solids. The housing is designed to contain the filter press and provide a seal around the plunger.

How Does a Filter Press Work? – The Operation Process

The operation process of a filter press is relatively simple. The first step is to add the liquid to be filtered to the press. The liquid is then pressed through the filter cloth, creating a liquid and solid mixture.

The plunger is then used to apply pressure to the filter cloth, causing the liquid to pass through and leave behind the solids. The solid material is collected in the housing, and the process is repeated until the desired level of filtration is achieved.

Example:

A filter press is used in the food and beverage industry to remove impurities from fruit juice. The juice is added to the press, and the plunger is used to apply pressure to the filter cloth, creating a clean and pure juice.

Summary:

In conclusion, a filter press is a simple and effective tool for separating liquids and solids. By understanding the design and operation of a filter press, you can improve your industrial processes and achieve better results. Whether you’re in the food and beverage industry or another field, a filter press is a valuable tool to have in your arsenal.

Posted on November 20, 2023

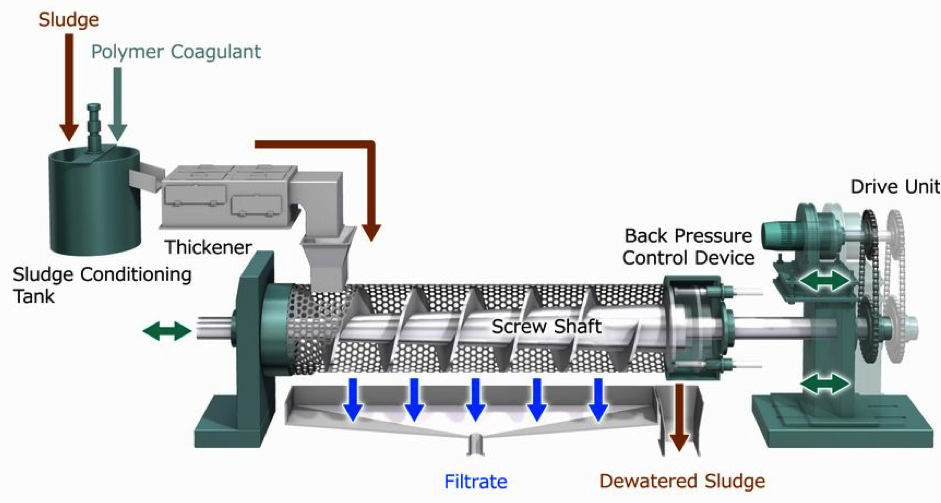

Screw Press Machine: Revolutionizing Industrial Processing

Explore the innovative capabilities of screw press machines in industrial processing. This article delves into the applications of screw press machines across various industries, from food processing to waste management. Discover the advantages of using screw press machines, including high efficiency, versatility, and cost-effectiveness.

Introduction:

Screw press machines have emerged as a game-changer in industrial processing. This article explores the applications and advantages of screw press machines across diverse industries.

From extracting juices and oils to dewatering and solid-liquid separation, screw press machines offer high efficiency, versatility, and cost-effectiveness. Join us as we uncover how screw press machines optimize production processes, enhance output quality, and minimize resource wastage.

Introduction to the Screw Press Machine:

A screw press machine is a versatile mechanical device designed to exert pressure and extract liquids or solids from various materials. It consists of a rotating screw or auger within a cylindrical barrel.

As the material is fed into the machine, the screw applies pressure, forcing the liquid or solid components to separate. The extracted liquid or dewatered solid is then discharged, while the remaining material undergoes further processing or disposal.

Applications of Screw Press Machines in Industrial Processes:

- Food Processing: Screw press machines are widely used in the food industry for extracting juices from fruits, vegetables, and herbs. They efficiently separate the liquid from the pulp, ensuring maximum yield and preserving the nutritional quality of the extracted juices.

- Oil Extraction: Screw press machines play a crucial role in the oil industry, enabling efficient extraction of oils from various seeds and nuts. They ensure high oil yield, superior quality, and reduced processing time compared to traditional extraction methods.

- Waste Management: Screw press machines are employed in waste management processes to dewater and compress organic waste such as sludge, manure, and food waste. These machines efficiently separate the liquid fraction, reducing waste volume and facilitating proper disposal or further treatment.

Advantages of Screw Press Machines for Efficient Production:

- High Efficiency: Screw press machines offer high processing efficiency due to their continuous operation and effective separation mechanism. They maximize production output while minimizing downtime, making them ideal for large-scale industrial operations.

- Versatility: Screw press machines can be customized and adapted to suit various materials and processing requirements. They can handle a wide range of substances, including different fruit and vegetable varieties, seeds, and waste materials.

- Cost-Effectiveness: Screw press machines provide cost savings by optimizing resource utilization. They extract maximum yield from raw materials, minimizing waste and reducing the need for additional processing steps.

- Improved Output Quality: Screw press machines ensure superior output quality by separating the desired components efficiently. They minimize contamination and maintain the integrity of extracted liquids or dewatered solids, resulting in higher-quality end products.

Example:

For instance, in the food industry, a screw press machine was utilized to extract juice from a variety of fruits. The machine efficiently separated the juice from the pulp, resulting in higher yield and improved product quality. The continuous operation of the screw press machine enabled consistent production, meeting the demands of the market while reducing processing time.

In conclusion, screw press machines have revolutionized industrial processing by offering high efficiency, versatility, and cost-effectiveness. Their applications range from food processing to waste management, enabling efficient liquid extraction and solid-liquid separation. Upgrade your production processes with screw press machines to boost output, reduce waste, and optimize resource utilization.

Posted on November 20, 2023

How does the pivot mechanism of iron doors impact their installation and operation?

The pivot mechanism in iron doors significantly influences both the installation process and their overall operation:

- Installation Precision: Installing iron doors with a pivot mechanism requires precise alignment of the pivot hardware. Ensuring that the pivot points are accurately positioned is crucial to achieve smooth operation.

- Structural Requirements: The pivot mechanism affects the structural requirements of the door frame and adjacent structures. It necessitates robust support to handle the weight of the door and the stress exerted on the pivot points.

- Door Stability: Properly installed pivot hardware contributes to the stability of the door. It allows the door to pivot smoothly without excessive swinging or sagging, enhancing its functionality and longevity.

- Swinging Action: The pivot mechanism determines the swinging action of the door. Whether it’s a center-hung pivot or an offset pivot, cheap iron doors the choice impacts how the door moves, influencing the visual aesthetics and practicality of the door’s operation.

- Weight Distribution: The pivot mechanism helps distribute the weight of the door more evenly, reducing strain on the hinges and ensuring balanced movement during operation.

- Size and Weight Capacity: The pivot mechanism’s design should accommodate the door’s size and weight. Larger and heavier doors require stronger and more robust pivot hardware to support their movement.

- Maintenance Needs: The pivot mechanism needs periodic inspection and maintenance to ensure smooth operation. Lubrication, adjustments, and checks for wear and tear are essential to prevent issues with functionality over time.

- Accessibility: Properly designed pivot mechanisms can enhance accessibility by allowing wider door openings, making them suitable for spaces where a standard swinging door might be impractical.

- Aesthetic Impact: The pivot hardware’s design can contribute to the door’s overall aesthetic. Sleek, minimalistic pivot hardware or decorative elements can complement the door’s design.

In summary, the pivot mechanism is pivotal (pun intended!) in ensuring the proper installation, stability, and functionality of iron doors. It affects various aspects of the door’s performance, from structural support to ease of operation, making it a crucial element in the design and functionality of these doors.

Iron pivot doors offer unique characteristics in both functionality and aesthetics compared to other types of doors:

Functionality:

- Smooth Operation: Pivot doors pivot on a central axis, allowing for smooth and effortless operation. They can swing in both directions, offering a wide opening and flexibility in movement.

- Large Size Handling: Pivot doors can accommodate larger sizes without compromising stability. They distribute weight more evenly, reducing stress on hinges and making them suitable for grand entrances.

- Accessibility: Due to their pivot mechanism, these doors can create wide and unobstructed openings, making them suitable for wheelchair access and high-traffic areas.

- Architectural Versatility: Pivot doors offer flexibility in architectural design, allowing for innovative and modern entrances in both residential and commercial settings.

- Statement Piece: They serve as a focal point and a statement piece due to their grand size, unique movement, and potential for artistic detailing.

Aesthetics:

- Elegance and Grandeur: Iron pivot doors exude elegance and grandeur, adding a luxurious touch to the entrance of a property.

- Artistic Expression: The material allows for intricate designs, artistic patterns, and customization, enhancing the door’s aesthetic appeal.

- Modern and Contemporary: They often complement modern and contemporary architectural styles, offering a sleek and sophisticated appearance.

- Versatile Finishes: Iron pivot doors can feature various finishes such as textured coatings, patinas, or unique surface treatments, contributing to their aesthetic versatility.

- Distinctive Presence: Their imposing presence and unique pivot movement create a distinctive visual impact, setting them apart from standard hinged or sliding doors.

However, while iron pivot doors have these advantages, they might not suit every architectural setting or functional requirement. Other door types, such as sliding, hinged, or folding doors, have their own advantages in terms of space-saving, ease of installation, and cost-effectiveness. The choice often depends on specific design preferences, available space, and functional needs of the property.

Posted on November 20, 2023

What are the design trends or innovations emerging in the realm of iron pivot doors?

How does the weight of iron pivot doors affect their installation and functionality?

The weight of iron pivot doors significantly impacts both their installation and functionality in several ways:

- Installation Challenges: Iron pivot doors tend to be heavier compared to standard hinged doors. The weight can pose challenges during installation, requiring adequate support and specialized handling.

- Structural Requirements: Installing heavy pivot doors demands robust structural support, ensuring that the doorframe, floor, and adjacent walls can withstand the weight and stress exerted by the door.

- Pivot Mechanism: The weight of the door impacts the pivot mechanism’s functionality. Properly sized and sturdy pivot hardware is essential to ensure smooth swinging motion and prevent strain on the pivot system.

- Operation and Accessibility: Heavy doors might require more effort to operate, impacting ease of use. Properly balanced pivots and well-maintained hinges are crucial for seamless functionality.

- Flooring Considerations: The weight distribution of iron pivot doors, especially in larger sizes, requires attention to the flooring material and foundation to prevent sagging or misalignment over time.

- Installation Expertise: Due to the weight and complexity of iron pivot doors, professional expertise is often necessary for proper installation. Skilled installers have the knowledge and tools to handle the weight and ensure precise fitting.

- Safety Risks: Heavy doors pose safety risks during installation if not handled properly. Mishandling can cause injury to installers or damage to the door and surrounding structures.

- Maintenance Challenges: The weight of iron pivot doors might necessitate more frequent maintenance to ensure proper functionality, including checks on pivot hardware, lubrication, and structural integrity.

- Architectural Considerations: Designing spaces to accommodate heavy pivot doors involves careful planning and consideration of load-bearing capacities, clearances, and structural reinforcements.

In essence, the weight of iron pivot doors requires meticulous planning, robust structural support, and professional installation to ensure smooth operation, minimize stress on pivot mechanisms, and prevent structural issues. Properly addressing the weight-related challenges is crucial to maintain the functionality and longevity of iron pivot doors.

Posted on November 14, 2023

Filter Press Sludge: A Comprehensive Guide

Filter press sludge, also known as filter cake, is a byproduct of the filter press process used in various industries such as wastewater treatment, mining, and food processing. It is a complex mixture of solids and liquids that requires proper management and disposal to avoid environmental and health hazards.

Characteristics of Filter Press Sludge

Filter press sludge is a semi-solid material that consists of a mixture of solid particles, water, and other contaminants. Its physical and chemical properties vary depending on the specific application and the type of filter press used. However, it generally has a high solid content, ranging from 10% to 30%, and a particle size distribution that is largely dependent on the filter press’s mesh size.

Handling and Storage of Filter Press Sludge

The handling and storage of filter press sludge require careful consideration to prevent environmental and health hazards. The sludge should be collected and stored in airtight containers or tanks to prevent odor and dust emissions.

It is important to avoid exposing the sludge to rain or sunlight, as this can cause it to become soggy and difficult to handle. In addition, the storage area should be secured to prevent unauthorized access and potential contamination.

Disposal Methods of Filter Press Sludge

There are several disposal methods for filter press sludge, including landfill disposal, incineration, and recycling. Landfill disposal is the most common method, which involves transporting the sludge to a licensed landfill site and disposing of it by local regulations.

Incineration is another option, which involves burning the sludge to produce energy or ash. Recycling is also becoming increasingly popular, which involves treating the sludge to recover valuable materials such as metals and nutrients.

Conclusion

In conclusion, filter press sludge is a byproduct of the filter press process that requires proper management and disposal. Its characteristics, handling, and storage require careful consideration to prevent environmental and health hazards.

Disposal methods such as landfill disposal, incineration, and recycling are available, and the choice of method depends on various factors such as cost, regulations, and environmental impact. By understanding the properties and management practices of filter press sludge, industries can minimize its impact on the environment and ensure a sustainable future.

Posted on November 8, 2023

Enhancing Sludge Dewatering Efficiency with a Filter Press

Discover the benefits of using a filter press for efficient sludge dewatering. This comprehensive guide provides insights into the functionality of a filter press and its role in separating liquid and solid components from sludge.

Understanding the Filter Press for Sludge Dewatering

A filter press is a specialized equipment used in sludge dewatering processes. It operates by applying pressure to sludge, separating the liquid (filtrate) from the solid components.

The filter press consists of a series of plates with filter cloths that retain the solids while allowing the filtrate to pass through. This versatile equipment offers several advantages for sludge dewatering applications.

Key Benefits and Applications of a Filter Press

Efficient Solid-Liquid Separation: The filter press effectively separates liquid and solid components, resulting in a high degree of dewatering. It enables the extraction of a significant amount of water from the sludge, reducing its volume for disposal or further treatment.

Versatile Application: Filter presses are widely used across various industries, including wastewater treatment plants, mining operations, chemical manufacturing, and food processing. They are suitable for dewatering different types of sludge, such as municipal, industrial, and biological sludge.

Operating Considerations and Successful Applications

Proper Filter Cloth Selection: Choosing the appropriate filter cloth is crucial for efficient sludge dewatering. Factors such as particle size, chemical composition, and desired filtration efficiency should be considered to ensure optimal performance.

Pressure and Cycle Time Optimization: Adjusting the pressure and cycle time of a filter press can enhance dewatering efficiency. Proper optimization allows for the removal of more water from the sludge, resulting in a higher cake solids content.

Example Application:

For example, in a wastewater treatment plant, a filter press is used to dewater the sludge generated during the treatment process. By applying the appropriate pressure and selecting the right filter cloth, the filter press efficiently separates the water from the sludge.

Producing a drier cake with reduced volume. The filtrate can be recycled or further treated, while the dewatered sludge can be easily disposed of or used for beneficial purposes, such as fertilizer production.

Conclusion:

In conclusion, utilizing a filter press for sludge dewatering provides numerous benefits, including efficient solid-liquid separation and versatile application across various industries. By considering factors such as filter cloth selection, pressure optimization, and cycle time adjustment, you can enhance the performance of the filter press and achieve optimal dewatering results.

Real-life applications demonstrate the successful utilization of filter presses in wastewater treatment plants and other industries. Streamline your sludge dewatering process and improve overall efficiency by incorporating a filter press into your operations.