Posted on November 20, 2023

Screw Press Machine: Revolutionizing Industrial Processing

Explore the innovative capabilities of screw press machines in industrial processing. This article delves into the applications of screw press machines across various industries, from food processing to waste management. Discover the advantages of using screw press machines, including high efficiency, versatility, and cost-effectiveness.

Introduction:

Screw press machines have emerged as a game-changer in industrial processing. This article explores the applications and advantages of screw press machines across diverse industries.

From extracting juices and oils to dewatering and solid-liquid separation, screw press machines offer high efficiency, versatility, and cost-effectiveness. Join us as we uncover how screw press machines optimize production processes, enhance output quality, and minimize resource wastage.

Introduction to the Screw Press Machine:

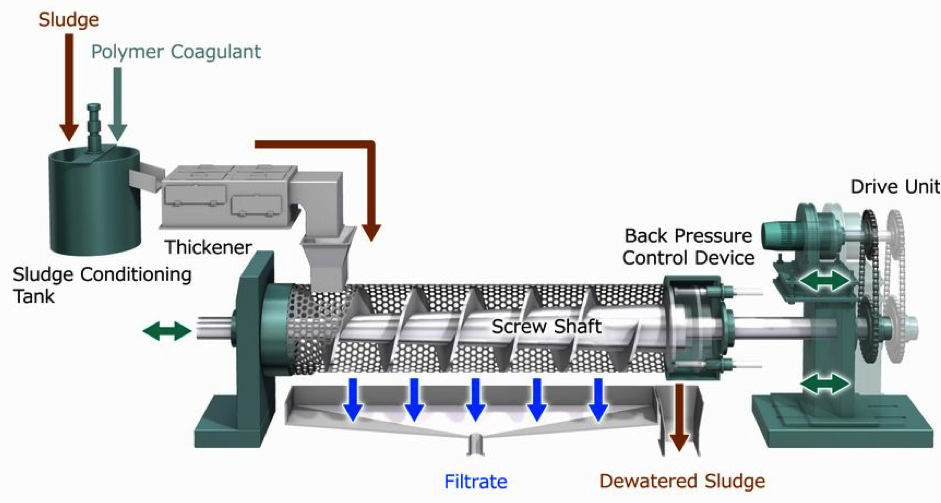

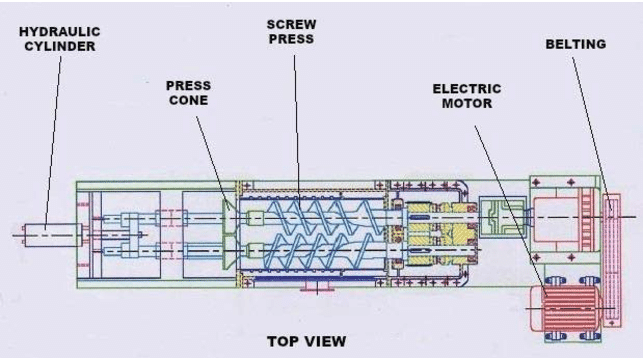

A screw press machine is a versatile mechanical device designed to exert pressure and extract liquids or solids from various materials. It consists of a rotating screw or auger within a cylindrical barrel.

As the material is fed into the machine, the screw applies pressure, forcing the liquid or solid components to separate. The extracted liquid or dewatered solid is then discharged, while the remaining material undergoes further processing or disposal.

Applications of Screw Press Machines in Industrial Processes:

- Food Processing: Screw press machines are widely used in the food industry for extracting juices from fruits, vegetables, and herbs. They efficiently separate the liquid from the pulp, ensuring maximum yield and preserving the nutritional quality of the extracted juices.

- Oil Extraction: Screw press machines play a crucial role in the oil industry, enabling efficient extraction of oils from various seeds and nuts. They ensure high oil yield, superior quality, and reduced processing time compared to traditional extraction methods.

- Waste Management: Screw press machines are employed in waste management processes to dewater and compress organic waste such as sludge, manure, and food waste. These machines efficiently separate the liquid fraction, reducing waste volume and facilitating proper disposal or further treatment.

Advantages of Screw Press Machines for Efficient Production:

- High Efficiency: Screw press machines offer high processing efficiency due to their continuous operation and effective separation mechanism. They maximize production output while minimizing downtime, making them ideal for large-scale industrial operations.

- Versatility: Screw press machines can be customized and adapted to suit various materials and processing requirements. They can handle a wide range of substances, including different fruit and vegetable varieties, seeds, and waste materials.

- Cost-Effectiveness: Screw press machines provide cost savings by optimizing resource utilization. They extract maximum yield from raw materials, minimizing waste and reducing the need for additional processing steps.

- Improved Output Quality: Screw press machines ensure superior output quality by separating the desired components efficiently. They minimize contamination and maintain the integrity of extracted liquids or dewatered solids, resulting in higher-quality end products.

Example:

For instance, in the food industry, a screw press machine was utilized to extract juice from a variety of fruits. The machine efficiently separated the juice from the pulp, resulting in higher yield and improved product quality. The continuous operation of the screw press machine enabled consistent production, meeting the demands of the market while reducing processing time.

In conclusion, screw press machines have revolutionized industrial processing by offering high efficiency, versatility, and cost-effectiveness. Their applications range from food processing to waste management, enabling efficient liquid extraction and solid-liquid separation. Upgrade your production processes with screw press machines to boost output, reduce waste, and optimize resource utilization.