Posted on November 24, 2023

How Does a Filter Press Work?

Are you curious about how a filter press works? Look no further! In this article, we will provide a comprehensive guide on the basics of filter presses, including their design, operation, and benefits. Whether you’re a seasoned professional or just starting out.

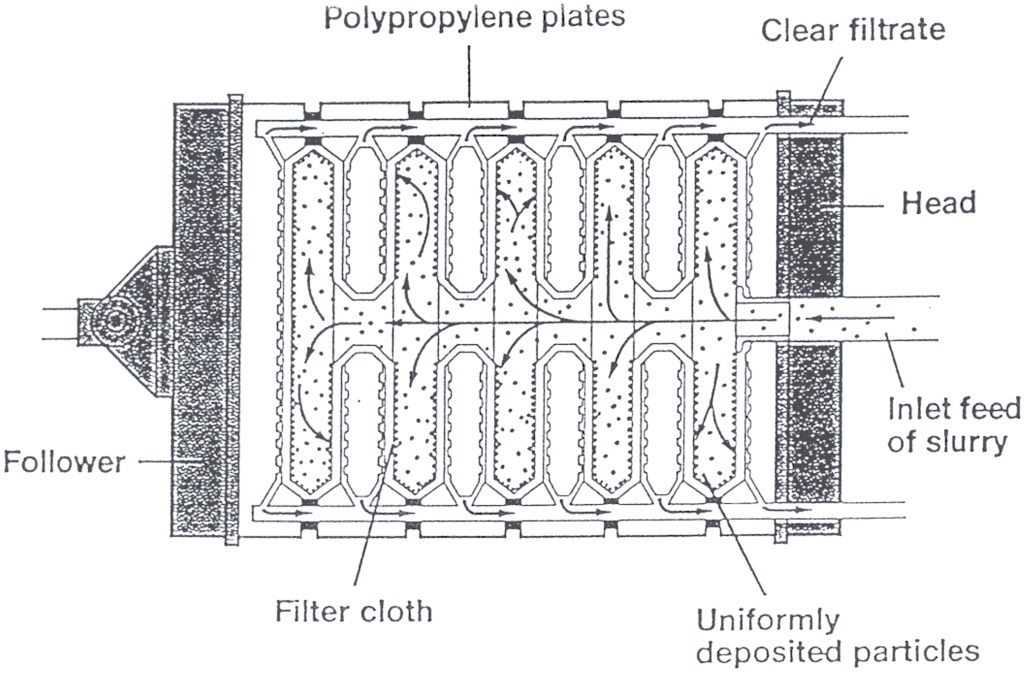

Filter Press Design and Construction

A filter press is a type of fluid press that is used to separate liquids and solids. The basic design consists of a plunger, a filter cloth, and a housing. The plunger is used to apply pressure to the filter cloth, causing the liquid to pass through the cloth and leave behind the solids. The housing is designed to contain the filter press and provide a seal around the plunger.

How Does a Filter Press Work? – The Operation Process

The operation process of a filter press is relatively simple. The first step is to add the liquid to be filtered to the press. The liquid is then pressed through the filter cloth, creating a liquid and solid mixture.

The plunger is then used to apply pressure to the filter cloth, causing the liquid to pass through and leave behind the solids. The solid material is collected in the housing, and the process is repeated until the desired level of filtration is achieved.

Example:

A filter press is used in the food and beverage industry to remove impurities from fruit juice. The juice is added to the press, and the plunger is used to apply pressure to the filter cloth, creating a clean and pure juice.

Summary:

In conclusion, a filter press is a simple and effective tool for separating liquids and solids. By understanding the design and operation of a filter press, you can improve your industrial processes and achieve better results. Whether you’re in the food and beverage industry or another field, a filter press is a valuable tool to have in your arsenal.